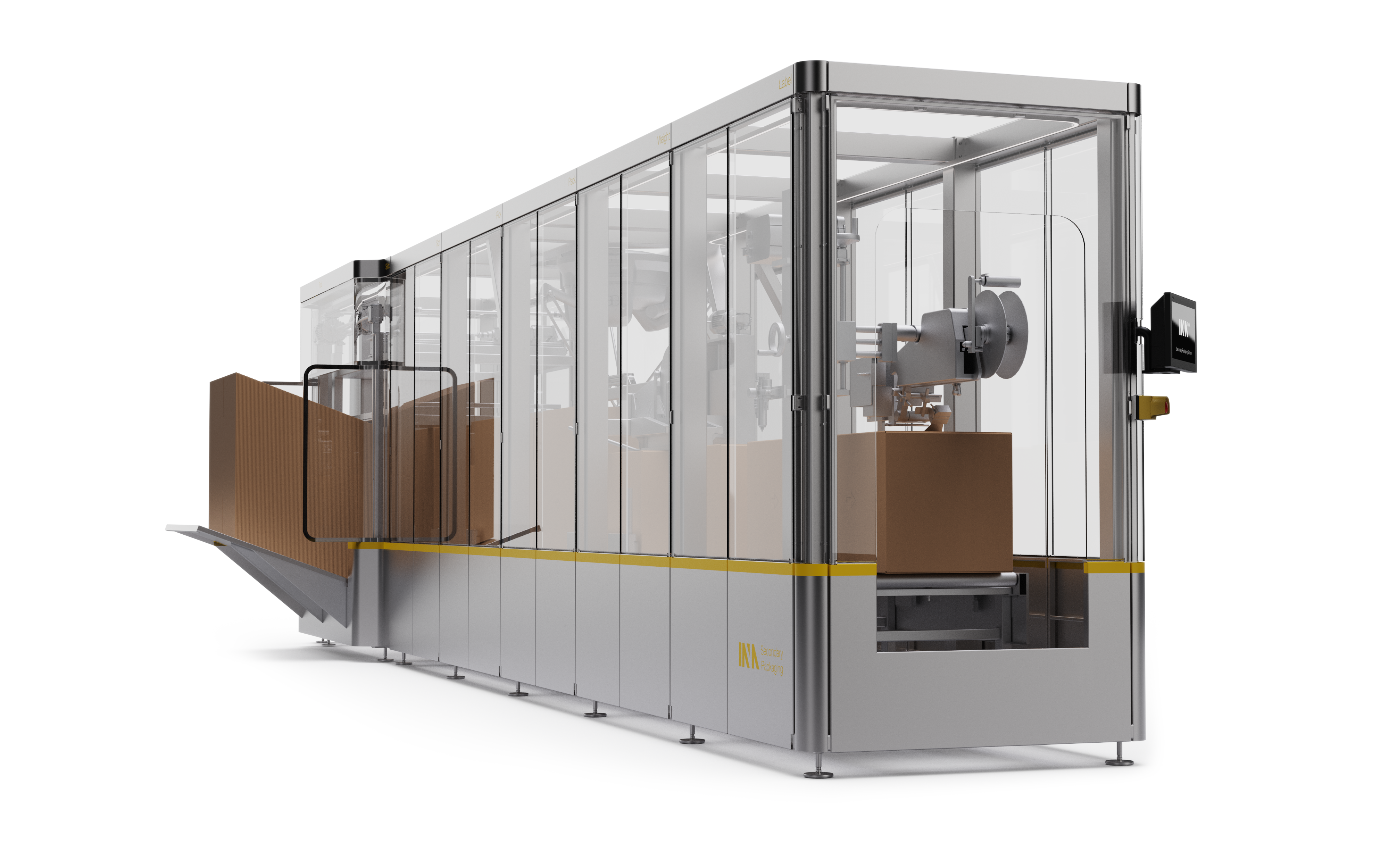

INNA Pack was designed as a modular system with the ability to adapt and create tailored solutions. Modular design enables a custom-made configuration, which adds maximum versatility and efficiency to any packing process. It allows for a variety of products to be packed on the same line and creates precise solutions for specific requirements.

Explore standard functions:

Our fully automatic machine retrieves the cardboard blanks, opens, folds and forms boxes in different sizes and formats.

We use ABB FlexPicker® witch is the fastest industrial delta robot in the world offering high reliability and accuracy for payloads up to 8kg.

Our machine includes automatic flap folding device as well as top and bottom case taping machines to achieve full transport readiness.

We included weight control unit at the end of the line to completely eliminate chance of packaging errors

Our machine is capable to apply different label information for each case to help manage and track production, storage or shipping.

Modular design enables a custom-made configuration, which adds maximum versatility and efficiency to any packing process.

Our fully automatic machine retrieves the cardboard blanks, opens, folds and forms boxes in different sizes and formats.

We use ABB FlexPicker® witch is the fastest industrial delta robot in the world offering high reliability and accuracy for payloads up to 8kg.

Our machine includes automatic flap folding device as well as top and bottom case taping machines to achieve full transport readiness.

We included weight control unit at the end of the line to completely eliminate chance of packaging errors

Our machine is capable to apply different label information for each case to help manage and track production, storage or shipping.

Modular design enables a custom-made configuration, which adds maximum versatility and efficiency to any packing process.

Explore our mashine in full 360 view

Robotics has been at the forefront of industry innovation for years, as it is proven to exceed the performance of monotonous human labour. Fully automotive, high volume, adaptive to specific requirements, produced and assembled in Europe, INNA Pack was designed to set standards in the secondary packaging industry.

With its’ minimalistic aesthetic and without compromising functionality, INNA Secondary Packaging System seeks to improve and redesign the conventional factory robotic systems. The system is designed to fit seamlessly into any manufacturing facility and improve the visual experience for humans sharing their workspace with extensive machinery.

Get the latest news, articles, and resources in your inbox weekly.